SOUTH STAR

South Star is a global manufacturer of precision heat exchange solutions for the home appliance and HVAC industries.

Since 2007, we’ve built a strong presence across Southeast Asia, specializing in copper, aluminum, and microchannel technologies—all backed by certified quality systems and efficient production.

With a focus on innovation and sustainability, we develop next-generation solutions like Micro Channel Heat Exchanger(MCHX) to improve performance and reduce environmental impact. At South Star, we don’t just follow industry trends—we engineer what comes next.

- Experience. Transparency. Results.

With over 15 years of dedicated manufacturing expertise, South Star delivers high-precision components trusted by global appliance brands. Our proven track record ensures consistent quality, cost efficiency, and scalable production across Southeast Asia.

Manufacturing 50 million units/year.

IATF 16949 ISO 9001 ISO 14001

Partner with South Star for Sustainable Growth

We are committed to delivering high-quality, cost-effective solutions tailored to your needs.

Start your journey with South Star and experience service excellence built on trust, innovation, and proven results.

Core Strengths

Delivering innovation, quality, and sustainable value across the global heat exchanger industry.

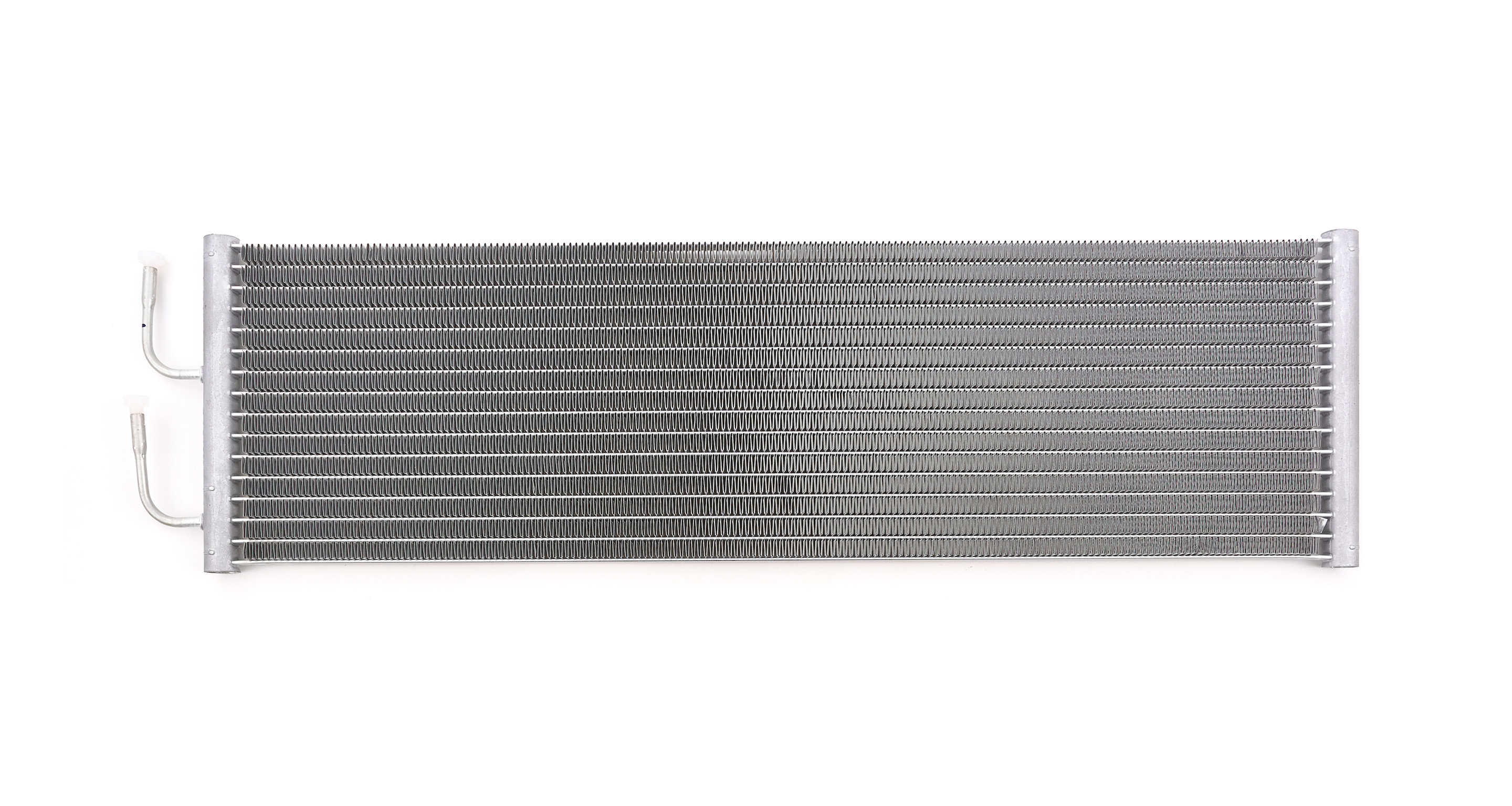

Development and mass production of Micro Channel Heat Exchanger(MCHX) to replace traditional aluminum fin & copper tube and wire condensers. Achieves top-tier energy efficiency (eligible for 5-star ratings) while expanding internal storage space in refrigerators. Enables additional cost savings by downsizing compressors, reducing steel plate thickness, and minimizing polyurethane usage.

Strategic production bases established across Southeast Asia: Rayong and Sriracha in Thailand, and Binh Duong in Vietnam Certified with ISO 9001, ISO 14001, and IATF 16949 for quality assurance Recognized for quality excellence with the 2024 SHARP Thailand Best Quality Award.

Successful copper usage reduction by up to 87.7% through in-house Eutectic Welding Technology and Al-Cu pipe application From in-house aluminum-copper pipe technology to advanced microchannel heat exchanger production, South Star continuousl y invests in new technologies to enhance performance, reduce costs, and deliver greater value to our partners.

- Solutions

High-Quality, Cost-Effective

We deliver cost reduction solutions without compromising product quality, helping our customers achieve better efficiency and competitiveness.

Since our founding in 2007, South Star has pursued a clear vision: building a strong manufacturing foundation to lead the future of heat exchange solutions. With continuous efforts to enhance our standards, we achieved global certifications early on and expanded our presence into new markets. Strategic investments in new facilities across Southeast Asia strengthened our production capabilities, enabling us to respond swiftly to evolving industry needs. Recognizing the need for innovation, we expanded into advanced technologies, such as heat exchanger development and injection molding, ensuring higher performance and greater value. Our commitment to technological advancement continued with the adoption of aluminum-aluminum laser welding and the launch of microchannel heat exchanger production. Today, South Star stands as a trusted partner for companies seeking reliable, efficient, and sustainable manufacturing solutions. And our journey is just beginning.